Do you have a custom metal fabrication project you need completed? Do you have questions about how the process works? P&D Metal Works in Neenah, WI, provides custom metal fabrication services for businesses and individuals across Northeast Wisconsin and the Fox Valley area and we may be able to help answer your questions and help you accomplish your goals.

You may have questions like — what is the metal fabrication design process? With the P&D Metal Works design and production teams, we will help you every step of the way — from design to installation. Here is a closer look at how the metal fabrication design process works at P&D Metal Works.

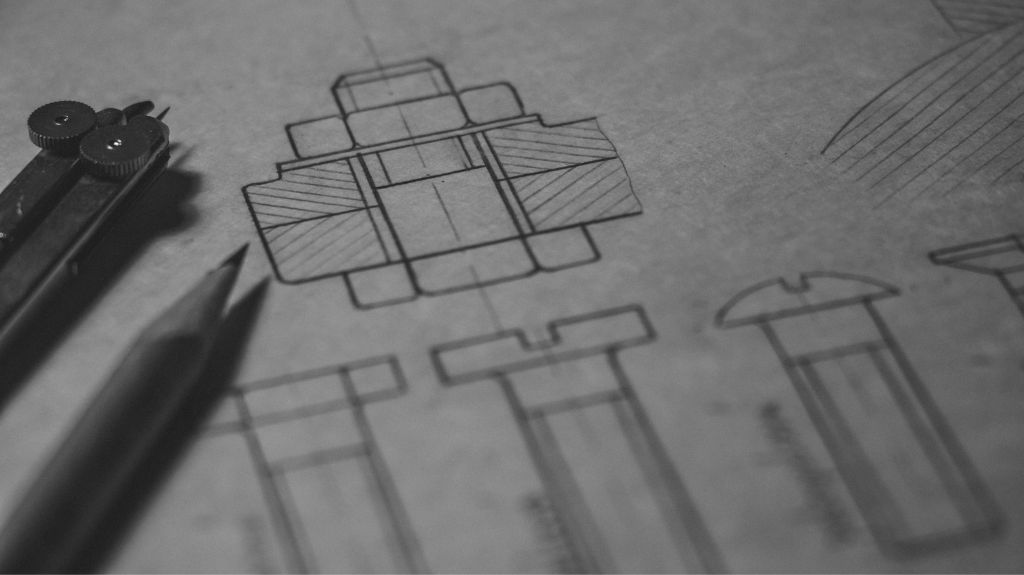

Step-by-Step Metal Fabrication Design Process

The metal fabrication process primarily consists of three steps — Planning and Design, Prototyping, and Design Finalization. Each phase of the process will help you get closer to your project goals and includes different aspects that help ensure that production runs smoothly and deadlines are met.

Here is a better look at what each step of the design process entails and what you can expect:

READ MORE: Top 5 Reasons to Choose a Local Metal Fabricator

1. Planning and Design Step

This phase of the design process is where customers will meet with a design team to discuss the project specifications and provide design engineers with an outline of functional needs for the finished product. The design team will create two-dimensional and three-dimensional models of the end product with CAD software to aid in visualization. With this step of the process, customers and design teams will determine the best material for metal fabrication based on manufacturing and budget requirements. This step will also further highlight the manufacturing steps and how the project concept will become reality.

2. Prototyping

This step in the design process may depend on the overall design and purpose of your metal fabrication project. More complex projects may require a prototype — either physical or virtual — to determine if the end product will work as intended or function with other components. This allows customers to test the functionality of the product and its quality. In addition to these aspects — the prototyping phase allows for customer feedback that can aid in making improvements to the product before it reaches the production phase.

3. Design Finalization

This is the final step of the metal fabrication design process. At this stage of the game — customers approve the design, so that the project can move to and begin production. With this step, customers and design engineers will create manufacturing instructions and blueprints for the project, before it is transferred over to the production team.

READ MORE: What Factors Affect the Cost of Custom Metal Fabrication?

Do you have a metal fabrication project you need completed? You may have questions like — what is the metal fabrication design process — and P&D Metal Works is here to help answer your questions with this overview of the process.

Contact P&D Metal Works today for more information on our metal fabrication services!